From Burnout to Balance

Today’s featured startup is building a platform that uncovers hidden stress patterns inside teams, turning sentiment data into insights leaders can act on immediately

Project Overview

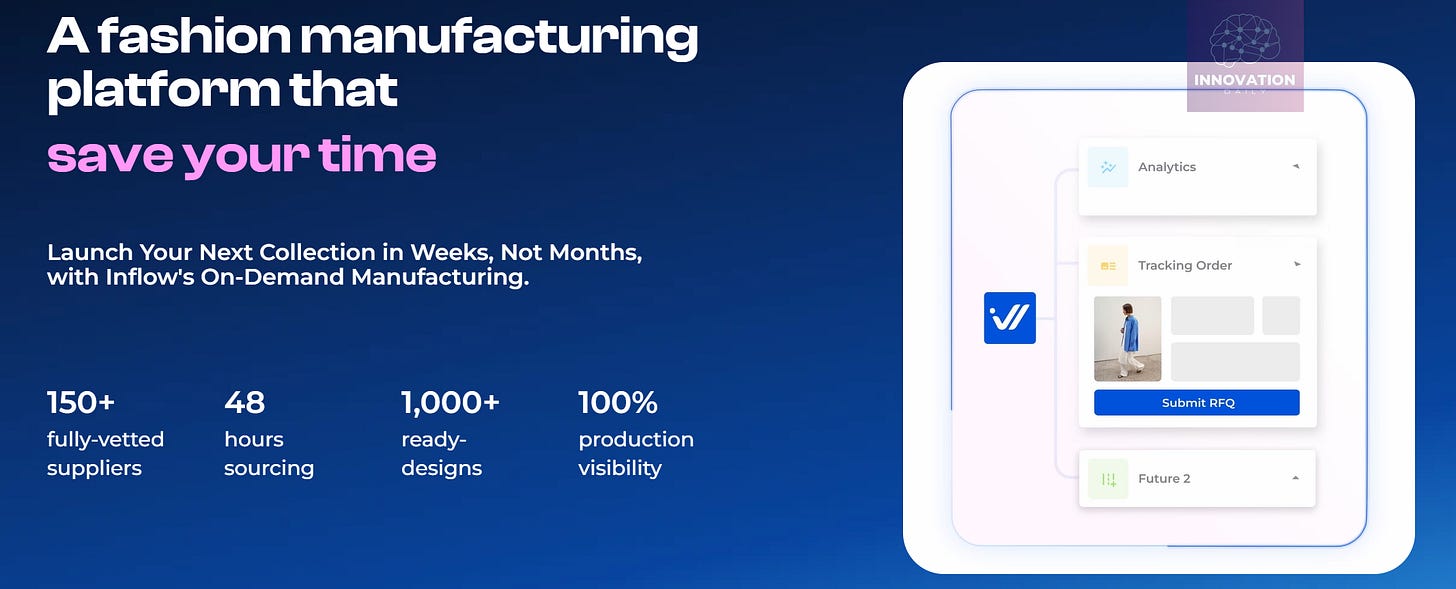

Inflow is a manufacturing platform that connects fashion brands with factories capable of producing their clothing and footwear.

The startup is based in Vietnam, which is why its initial focus has been on onboarding local manufacturers — over 150 factories have already joined the platform.

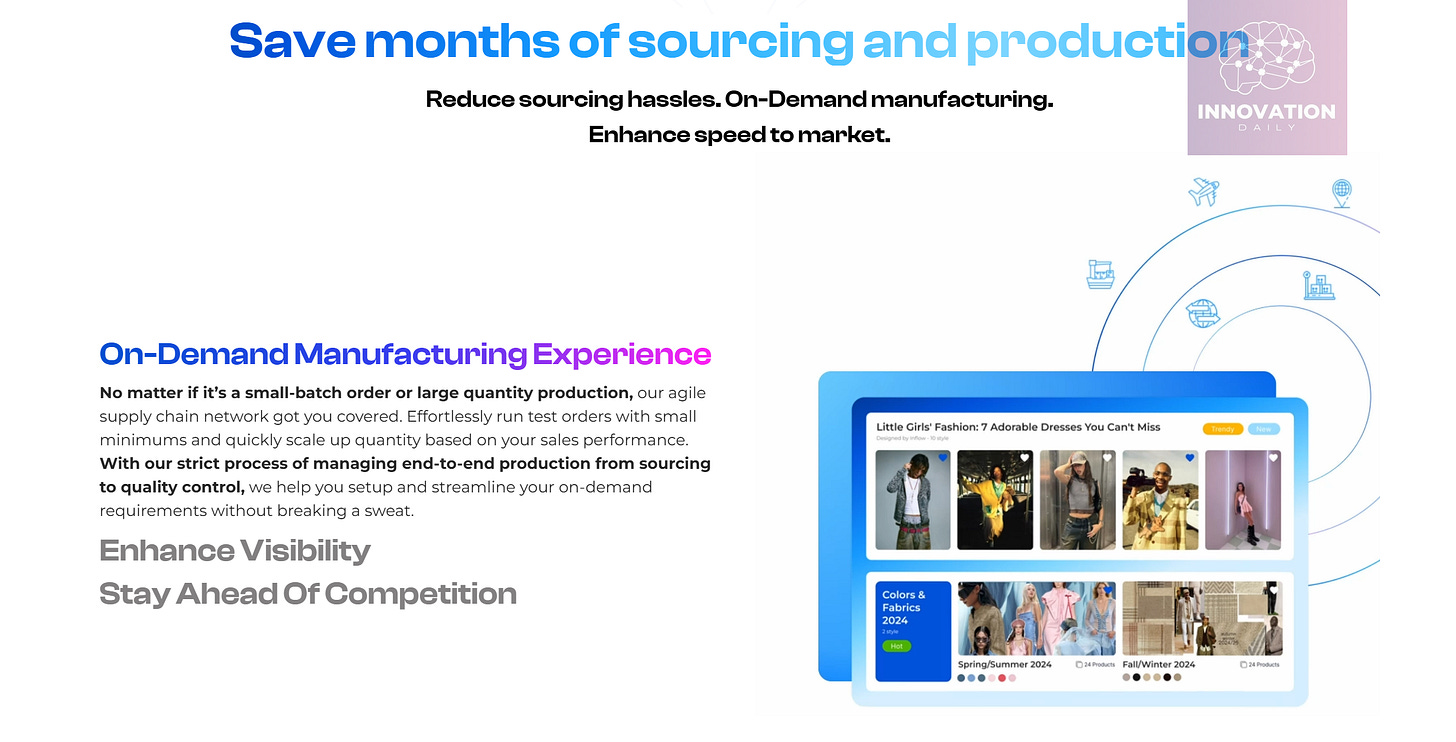

A brand starts by uploading a design — either its own or one selected from Inflow’s extensive library of ready-to-produce templates. Inflow’s specialists then take over: within 48 hours, they identify suitable factories, confirm availability, and deliver a shortlist with pricing and production terms.

Once a brand selects a factory, Inflow coordinates the creation of product samples, including variations in colors and fabrics. Samples take around 2 weeks when custom designs are used, and even less when choosing from the platform’s catalog. Brands receive samples for quality verification before moving to mass production.

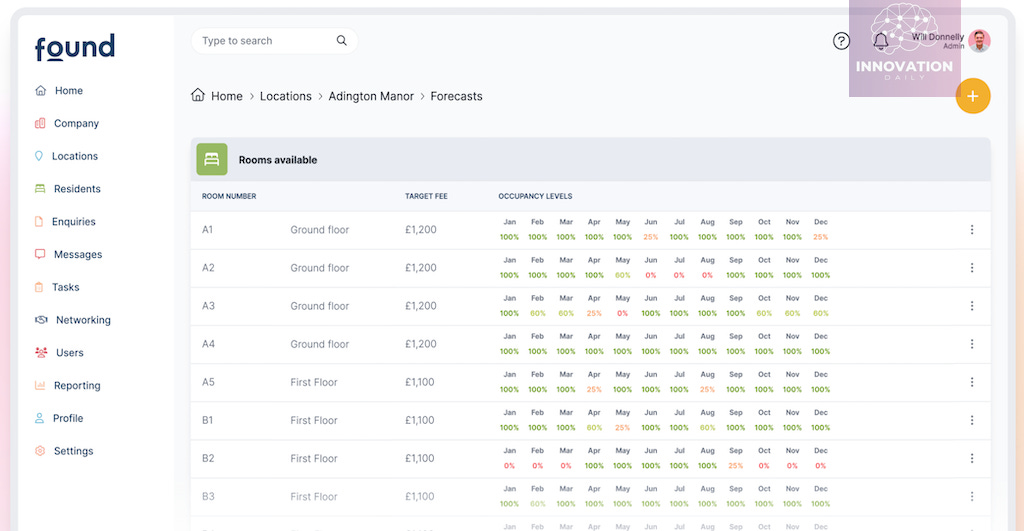

Production progress is tracked in real time through a dedicated dashboard.

Current minimum order quantity is 100 units with up to 45 days for production, but the team plans to reduce this to 50 units and 30 days, respectively.

Factories ship finished products directly to end customers. Brands can integrate their online stores with Inflow or upload order lists manually. Packaging and shipping statuses are also visible on the platform. Inflow monitors production quality and resolves issues with factories on behalf of brands.

Although the startup launched only last year, about 80 brands — mostly in Southeast Asia — have already begun using the platform. Inflow claims even small brands with annual revenue starting from $200K can benefit. Over the past year, Inflow’s revenue grew 15×, and the company raised a $2M round.

What’s the Gist?

The model isn’t new — several startups have tried to build “manufacturing marketplaces,” but the execution varies dramatically.

Manufactured raised $19M building a similar platform for categories like appliances, electronics, cosmetics, and home goods.

SILQ, once a near-clone of Inflow, eventually pivoted to focus exclusively on logistics and quality control — largely because factories frequently missed production deadlines. The core issue: small factories usually have no proper planning or production management, relying on spreadsheets or even paper notes. A platform can’t guarantee reliable delivery if the factories themselves operate chaotically.

This created a new category of competitors, such as Groyyo, which approaches the same problem from the opposite direction: first digitize manufacturing (“digital factory” tools), then build the marketplace layer on top. Groyyo aims to digitize 20 million micro-manufacturers across Southeast Asia and has raised over $40M toward that goal.

The same structural problem appears in other industries. Without modern management tools on the supplier side, marketplaces fail — because suppliers cannot commit to reliable timelines.

A great example comes from a completely different vertical: Lottie. Initially just a directory of care homes in the UK, it couldn’t function as a true marketplace. After acquiring Found, a CRM for care homes, and integrating it, Lottie suddenly became a real marketplace with live availability — unlocking a better business model and a $20M investment round.

The lesson: to build a marketplace, you often must first digitize the supply side.

Key Takeaways

The fashion industry is entering a phase of unbundling. For decades, many fashion companies combined everything: brand, design, and in-house production. Now the market is splitting into two clear roles:

companies focused purely on brand building and design;

companies dedicated solely to manufacturing and scaling production.

This separation is inevitable — and it creates enormous demand for platforms that connect the two sides.

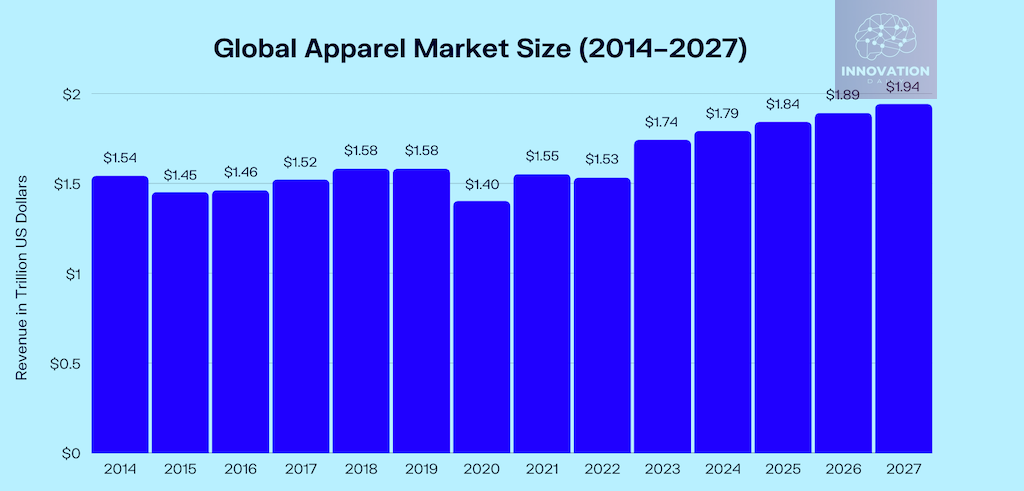

The apparel market is massive — nearly $2 trillion by 2027 — and platforms like Inflow are emerging to bridge brands and manufacturers in a more transparent, predictable way.

But the success of such platforms depends on the foundation: before connecting brands with manufacturers, you must digitize production itself. That’s why solutions like Groyyo’s “digital factory” and broader manufacturing-ops tools are becoming essential.

At the same time, complementary platforms will rise to help “pure brands” optimize their assortment without worrying about production constraints — companies like MakerSights, backed by $36.6M, already work in this direction.

Company Info

Inflow

Website: joininflow.io

Latest Round: $2M, 28.11.2023

Total Funding: $2.1M+ across 3 rounds